Contract manufacturing and low-volume batch in 1 size.

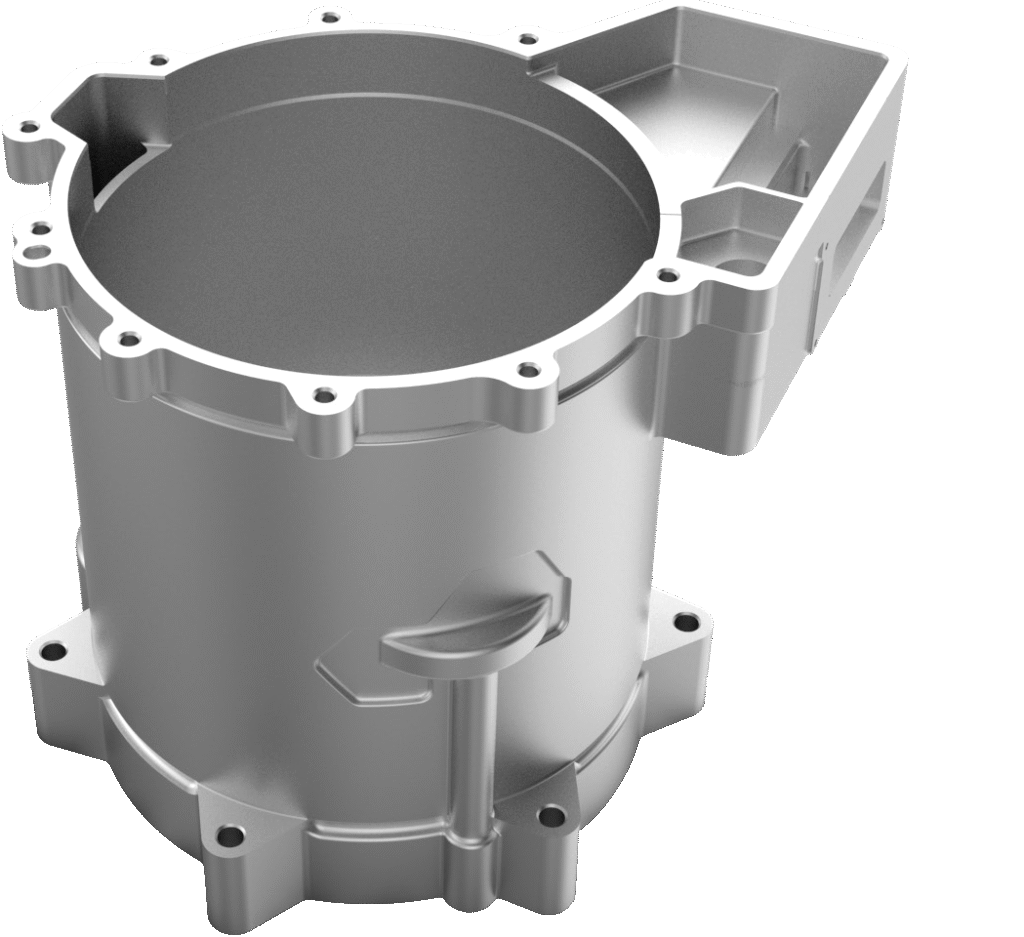

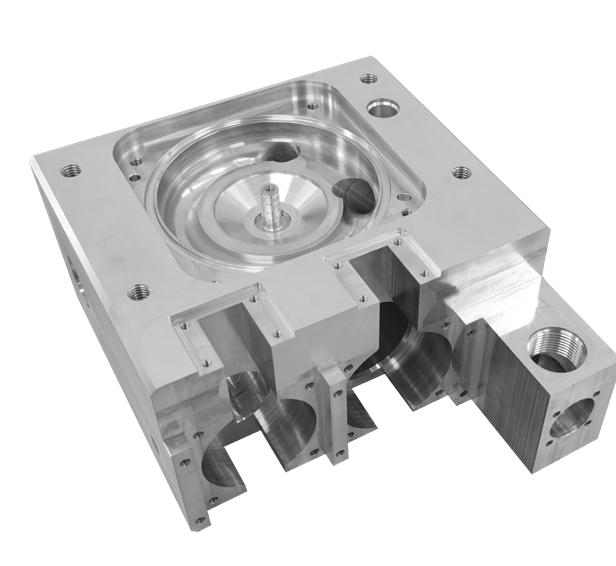

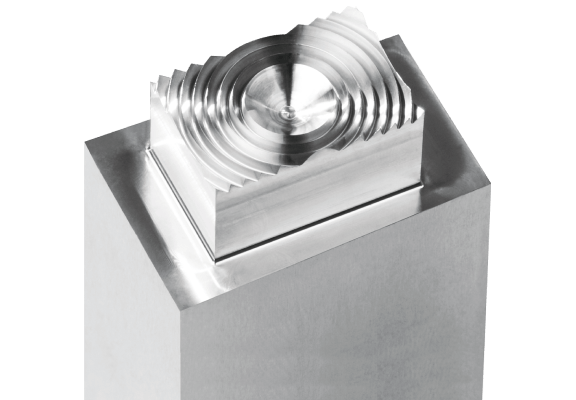

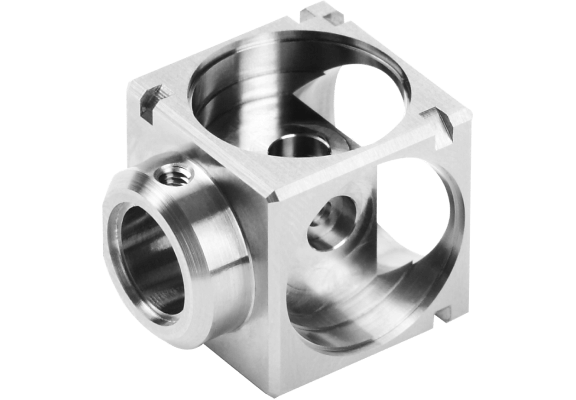

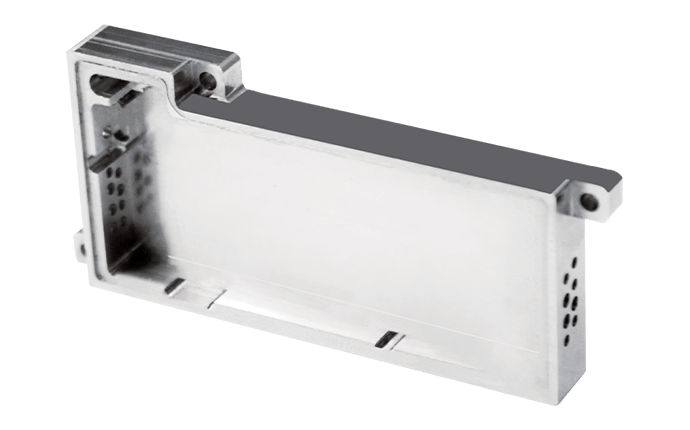

CNC machining for individual parts and small series. Do you want to produce batch size 1 at low cost? Then you are exactly right with us. Our core competence is the mechanical processing of individual parts and small series of up to 50 pieces.

Our machinery consists of modern CNC machines with large tool storage. This enables us to minimise set-up times even for small batch sizes and to manufacture cost-effectively. With our machines capability of workpieces up to 6 million in mobile phone size.

At our CAM workstations we work with feature recognition and can therefore also program new workpieces in the shortest possible time.

For you, this results in a very short lead time from quotation to surface treatment and delivery of the parts.

Test us, we are looking forward to your enquiry.

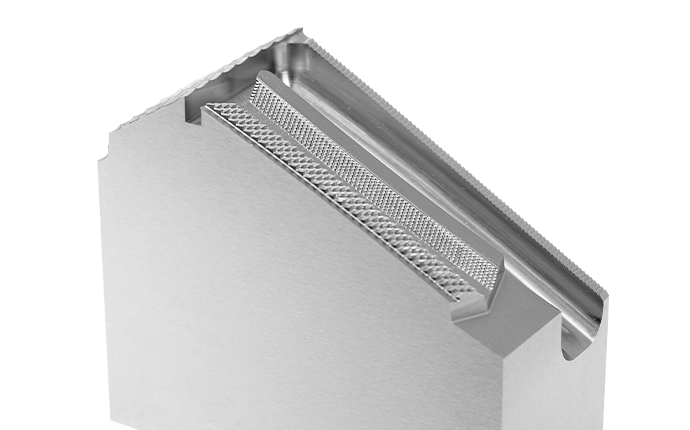

CNC Machining Capabilities

With a comprehensive ‘one-stop’ manufacturing service solutions, we integrate the factory’s manufacturing resources to ensure the high-quality delivery of customer parts on time.

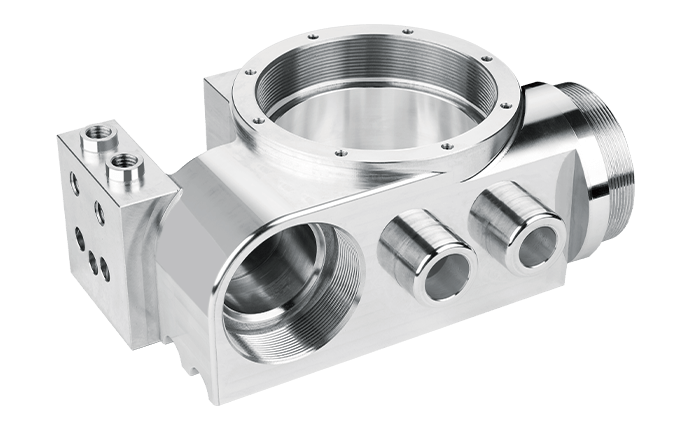

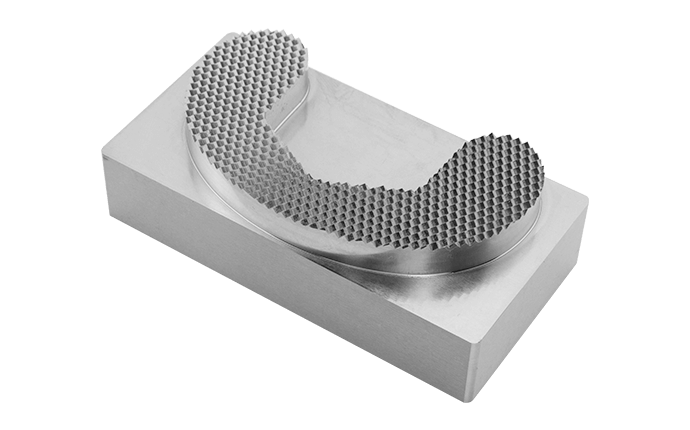

Additional technologies such as thread cutting, drilling, eroding and wire cutting round off the production spectrum.

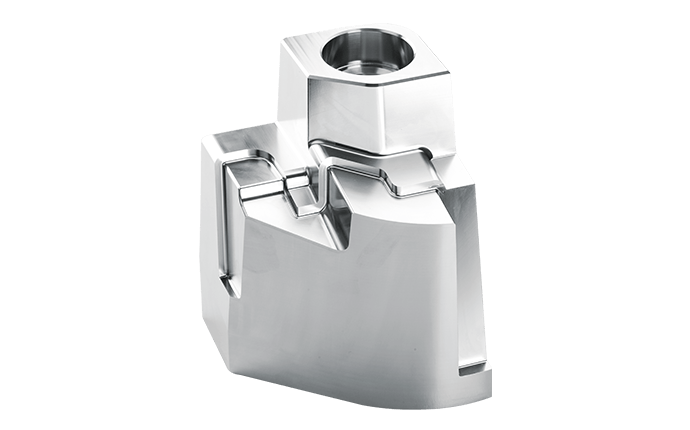

The machining accuracy can be stably achieved within 2~15μm, which meets the production requirements of complex shape precision small product parts.

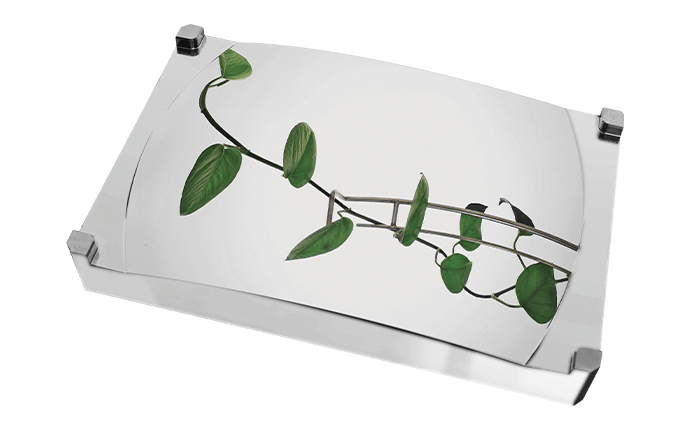

Sample Center

Processable metals

The metals that can be processed include aluminium, stainless steel, aluminium steels, bronze, brass, steel, titanium and carbon steel.

Processable plastics

Processable plastics include ABS, PC, PMMA, POM, PA, PP, PET, PVC, CPVC, PS, LDPE, HDPE, PSU, PPSU, nylon, PEEK, PEI and polycarbonates.

Tolerances

Our working methods are geared towards compliance with the ISO 2768 CNC machine standard. As a rule, the tolerances according to ISO 2768 (medium) and ISO 2768 (fine) are used. If tighter tolerances are required, a corresponding declaration in the drawings is necessary. Please contact us to discuss further options.

Possible component post-processing

The following technologies are available for processing:

Anodising, grinding and polishing, bead blasting and anodising, water plating, steam polishing, passivation, hard oxidation, powder coating, painting, chrome plating, electrophoresis, electropolishing, sandblasting, heat treatment, brushing, electroplating

Quick Turn(Mobile Phone Size)

- Simple1-2 Day

- Normal3 Day

- Complex5 Day

Please send your enquiries directly to our production manager Mr. robin. He will contact you as soon as possible.

Send enquiry Email:service@upperrapid.com

You can directly send the following data formats: Catia, NX, STEP, IGES, PRT, SLDPRT, DXF, and DWG.

High-Precision CNC Machining For Complex Geometries And Tight Tolerances. Ideal For Prototypes, Fixtures, And Small-Batch Production Where Accuracy Matters.

Customizable Processes, Fast Lead Time, And Engineering-Grade Finishes.

Contact us

Get instant quotes for cost-effective solutions : From confidential design-to-product services to fast delivery, we empower innovators with precision and speed. Contact us now!

Phone: +86 0592 373 1111

E-mail: service@upperrapid.com